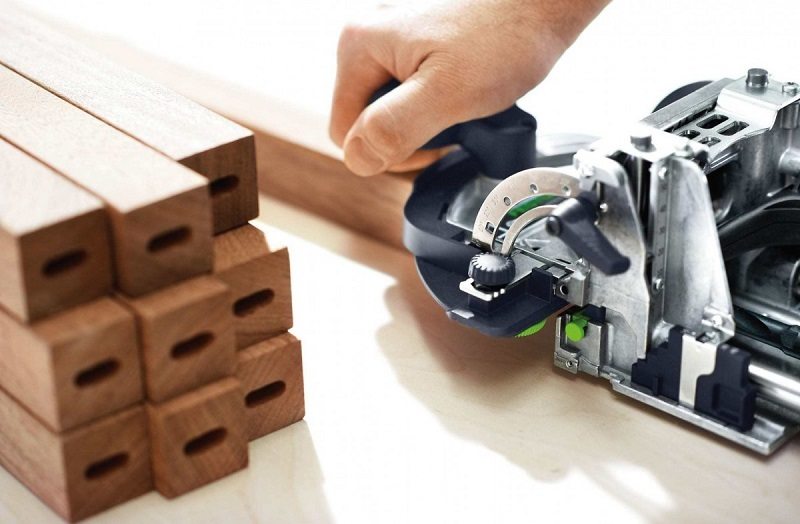

With domino sizes ranging from 4 mm to 14 mm thickness to versatile corner and flat knock down connectors, offering several connection options. For narrow or wide, delicate or solid workpieces. With the DOMINO connecting system all the benefits of round dowels and biscuits have been united into one for the first time. Whether it is a small drawer or a large, solid wood door – DOMINO is the solution. Many tradespeople have been converted to the DOMINO system. A connecting system that works simply and with considerably shorter set-up time and can be used for tasks that were previously only accomplished on stationary machines. This is a new complete wood connecting system, which assures the highest possible stability. We found the key for this in the patented pendulum routing movement and the resulting mortises for accepting the specially formed dominos. Thinking ahead in terms of a wood joint that unifies the benefits of all previously existing systems: the controversial stability of mortise and tenon, the flexibility of biscuits used in furniture making and the precision of the round dowel used in shelving. And yet it is also based just as much on the principle of thinking ahead. In truth, there are numerous innovations which were developed on the basis of a spontaneous idea. The DOMINO connecting system unites them all. Overview: making joints with the DOMINO joining machineįrame joints Mitered frame joints Butted frame joints Stable frame joints with the DOMINO DF 700Įvery wood joint has its advantages. Performing basic settings for the DOMINO joining machines Switching on/off Selecting mortise width Selecting domino length and thickness Cutter replacementĭepth adjustment range Height adjustment range Angle adjustment range Working with the stop system Working with dust extraction This allows for rapid building, moving, and reassembling of large pieces. These new connectors allow for rapid assembly of flat joints or corner joints utilizing Domino fasteners for knock- down design. The larger DOMINO XL DF 700 will create a mortise for the newly developed DOMINO Connectors. From its origins on a simple napkin, this concept continues to evolve. With the typical southern German inventiveness, infinite passion and the concentrated expertise of our engineers, a mix of traditional vertical bore and simultaneous horizontal routing movement was created – the birth of the DOMINO pendulum router principle as the driving force for the new DOMINO DF 500. That is to say, the development of a completely new tool. What was missing was the fitting mortise – and thus the real challenge began. Using the simple equation: make one from three, the DOMINO DF 500 domino system was set forth.

And finally a third for absolute ‘rotation resistance’ at the first attempt.

Then a second sketch next to it for a ‘larger glue surface’. And because nothing else was readily available, they sketched a domino on a napkin to represent the demand for ‘more stability’. They were dreaming what the optimal domino should be capable of. To be precise, it was initially only an informal exchange between two Festool employees over lunch. Yet the conversation and initial drawings where the idea was formed was on something a lot less imaginative: a napkin. There are numerous draft designs, CAD drawings, parts lists and documentation for our DOMINO connecting system.

The origin of a brilliant idea: DOMINO connecting system.

0 kommentar(er)

0 kommentar(er)